There are a few things to do before you jump right into the exercises. First, make sure you’ve completed the basic Onshape training. These 1188 training exercises assume that you have a basic understanding of 3D CAD modeling. Once you have a handle on the basics, read through the section below on how to read and interpret CAD drawings.

Abbreviations & Annotations

TYP. = Typical. In the context of drawings, it means that the feature being referred to repeats.

THRU = Through. This means that the hole or other feature passes all the way through the part.

⌀ = Diameter

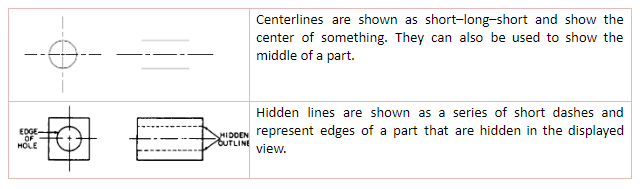

Line types

Different types of lines are used on drawings to convey information to the reader. A couple of the most common are shown below.

Although our robots can look very complex, they are mostly built up of simple parts. For this training, we will look at parts based on how they are manufactured. In general, we have 4 basic types of parts;

- 3D printed parts.

- CNC parts including sheet goods, such as polycarbonate and aluminum, as well as tube stock.

- Lathed parts which are almost exclusively shafts for us.

- COTS parts. COTS stands for the consumer-off-the-shelf part. In the context of FRC, these are parts that are purchased by the team from a supplier.

Each part has specific design considerations given how it will eventually be produced. For example, we are limited by the size of shafts we can make due to the size of our lathe.

With that basic understanding, we are going to jump right into CAD designing. For each exercise make a part in your folder on Onshape. If you do not have a folder, or you are not on the 1188 team, or you have not even signed up for Onshape, speak to a coach before proceeding.

NEXT – Exercise 1 – Frame tube